Rotaxane Actuators Study Unveils Promising Advancements for Drug Delivery Systems

Key Takeaways

Researchers from the University of Manchester have developed a technique using rotaxane actuators in force-controlled release systems, enabling precise and efficient release of multiple molecules simultaneously.

Research from the University of Manchester reveals a technique using rotaxane actuators in force-controlled release systems that show potential for advancement in drug delivery. Current methods lack mechanical stability, directly impacting the structural integrity of molecules and limiting drug effectiveness, according to the authors of the study published in Nature.

The authors discuss the capabilities of rotaxane actuators to improve the efficiency of drug delivery systems, enabling them to release multiple molecules.1 Specifically, this discovery marks the first time investigators have been able to show the ability of rotaxane actuators to release more than one component, making it one of the most efficient release systems to date.

Traditional controlled release mechanisms use polymers as actuators, which have proven limitations restricting their effectiveness, according to the study authors. Polymer actuators suffer from poor mechanical stability, making them prone to non-specific, uncontrolled release and dissociation after the first activation. As a result, they typically release only one molecule per activation.1

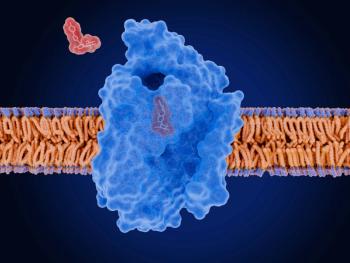

Unlike polymer actuators, which require structural changes for activation, rotaxane actuators respond directly to mechanical force (push, pull), allowing for more precisely controlled movement of the molecular structures. Rotaxane molecules have an interlocking architecture comprised of a macrocycle–a ring-shaped molecule–threaded onto a stoppered axle. The dumbbell-shaped structure prevents the macrocycle from freely sliding off the axle, thereby enhancing the efficiency of cargo release upon activation, the study authors explained.1

The study explores the influence of isomerism and the Diels-Alder reaction on the mechanical reactivity of rotaxane actuators, measuring success by the efficiency of cargo release and activation of adduct isomers under ultrasonication. Applying mechanical force pulls the macrocycle along the axle until it reaches the first Diels-Alder adduct. This adduct acts as a barrier, preventing the macrocycle from sliding off the axle, pulling it further against the adduct, and triggering the release of cargo molecules.1

Investigators equipped the rotaxane actuator with 3 model cargo molecules—a drug (doxorubicin), a fluorescent tag (N-[1-pyrenyl]maleimide), and an organocatalyst (tritylcation)—to demonstrate the versatility of rotaxane in accommodating different types of cargo. Cargo release success in each rotaxane was determined in 2 experiments by measuring the release efficiency of activation in solution and in bulk activation by compression.1

To activate the molecules using ultrasonication, they were attached to a Suslick cell, which was then dissolved and dried to remove any water. The solution was degassed using N2 for a minimum of 10 minutes, as well as for the duration of the experiment. Pulsed ultrasound was administered at a rate of 1 second on and 1 second off, with 25% amplitude (13.0 W cm−2), at a frequency of 20 kHz. They found the 3- and 5-cargo rotaxanes had release efficiencies of up to 44% and 22%, respectively, and random bond scission appeared in less than 40% and 50% of rotaxanes, respectively.1

When activated by manual compression, the study found the activation of 1-, 3- or 5-cargo rotaxanes to be less successful. The test involved compressing 30 mg of polymers containing the loaded rotaxanes by a manual press with 0.74 GPa, for less than 60 minutes per cycle, for 10 to 45 cycles total. Compared to activation in solution, this method demonstrated a lower proportion of rotaxanes releasing cargo molecules, possibly releasing up to 30% of the cargo load across the samples.1

The experiment results reveal the promising potential of rotaxane actuators, opening doors for developing more effective drug delivery systems with the ability to release multiple components simultaneously. Notable achievements in precisely controlled release, cargo versatility, and iterative activation have significant implications for the future of drug efficacy, potentially creating more effective drugs that can be taken at lower dosages.

Study authors also see potential for applying this technique to materials science. Rotaxane actuators’ control of cargo release could be used to develop materials that, when damaged, trigger the release of healing agents.1 Further studies aim to explore this self-healing application, as well as the potential to release 2 different types of molecules simultaneously.2

“Although this is only a proof-of-concept design, we believe that our rotaxane-based approach holds immense potential with far reaching applications,” said Guillaume De Bo, professor of Organic Chemistry at The University of Manchester, in a press release. “We’re on the brink of some truly remarkable advancements in health care and technology.”2

REFERENCES

1. Chen L, Nixon R, De Bo G. Force-controlled release of small molecules with a rotaxane actuator. Nature. 2024;628:320-325. doi.org/10.1038/s41586-024-07154-0

2. University of Manchester. Revolutionary molecular device unleashes potential for targeted drug delivery and self-healing materials. EurekAlert! April 10, 2024. Accessed April 18, 2024. https://www.eurekalert.org/news-releases/1040584

Newsletter

Stay informed on drug updates, treatment guidelines, and pharmacy practice trends—subscribe to Pharmacy Times for weekly clinical insights.