Following the Path of Antibody Structures to Biosimilars: A Journey in Innovation

Regulatory perspectives presented at ACR on biosimilars entering the market convey the importance of crafting antibodies to our own purposes.

During a session at the Annual Meeting of the American College of Rheumatology, John D. Isaacs, MD, PhD, FRCP, stated that his goal was not just to review regulatory perspectives, but to convey the essence of the biology: how can we craft antibodies to our own purposes?

From that, he said, one can look at the implications for creating and using biosimilars—a bio-therapeutic product similar in terms of quality, safety, and efficacy to an already-licensed and referenced bio-originated product—in clinical practice.

He then took the audience on a “journey” of the biological revolution of antibody structure/function and its attendant post-translational complexities, beginning in the late 19th century when 2 individuals developed an antitoxin for diphtheria to the late 20th century, when scientists realized they could clone antibodies.

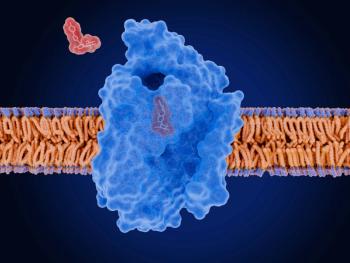

Isaac next presented detailed explanations of how researchers went from DNA to antibody heavy chains to antibody diversity, before making fully human antibodies. He then examined the pros and cons of nanobodies, followed by the development on the way to biosimilars of technology that permits the creation of bispecific monoclonal antibodies—with the whole point being to link an antibody with a function at the other end.

There are numerous steps along the way of developing and manufacturing a novel monoclonal antibody—including initial development, purification, drug substance, and formulation/sterilization. Because of the profusion of steps, however, the resulting product will vary.

The challenge for biosimilars, Isaac said, is that when dealing with optimization of a therapeutic antibody, researchers—in addition to developing the antibody—must also consider such issues as culture conditions and purification and formulation.

The challenge is to analyze what is in the bio-originator, and then replicate it. But because researchers are creating this product from human cells, they can only try to copy the bio-originator, because inherent in using a living system is a concomitant lack of control.

Regulatory requirements for new drugs begin with knowledge and follow a conventionally approved pathway that ends with several clinical studies. The biosimilar approval pathway, however, is essentially reversed.

Most of the money goes into analyzing the original antibody to make the biosimilar as close as possible. Comparative in vitro nonclinical studies—an array of side-by-side comparisons—must look similar all the way through. Also, safety and immunogenicity must be comparable and must continue to be assessed postmarketing. This process ends with at least 1 large clinical study to demonstrate clinical equivalence and safety derived from the meta-analysis of randomized controlled trials of the bio-originator.

Isaac delineated some of the advantages of using biosimilars. They are cheaper (their manufacturing processes are much more efficient), the regulatory requirements are abbreviated, the risk of failure is reduced (because they are using a drug that is already working), and the bio-originator itself becomes better characterized.

However, there are also disadvantages. They include different processes that could result in unpredicted effects or impurities in the final product, (eg, cell line and culture could be different). This, in turn, could influence half-life, aggregate formation, and immunogenicity (influenced by disease, genetics, concomitant therapies route of administration, dosing schedule, and efficacy and safety). Currently, pharmacists may not implement interchangeability (switching from the physician’s proscribed bio-originator to a biosimilar).

Isaac did think that this could change in the future, but stressed the critical importance of physicians prescribing by brand names. Isaac reiterated that the bio-originators in use today are not the same as those used 20 years ago, because researchers have found better ways of producing antibodies. Post translation modifications are more difficult to control, so they are not and, he emphasized, cannot be identical to the bio-originator product.

Lastly, he addressed cost. In Norway, which uses a competitive process, biosimilars costs one-third less than the reference product. In the United Kingdom, biosimilars are about 20% cheaper than originator drugs. He expects a 20% to 305 reduction in biosimilar costs in most countries in the near future.

Newsletter

Stay informed on drug updates, treatment guidelines, and pharmacy practice trends—subscribe to Pharmacy Times for weekly clinical insights.